The production landscape is constantly evolving, and automation is within the forefront of the transformation. specifically, automatic liquid filling is revolutionizing industries by enhancing performance, accuracy, and General productiveness. Choosing the correct liquid filling equipment available is critical for companies looking to stay competitive and satisfy the expanding demands of the industry. This article will check out the most up-to-date improvements in liquid filling devices, highlight the necessity of deciding upon the ideal company, and provide guidance on deciding on the excellent design on your precise sector application.

Table of contents:

Innovations in Liquid Filling Machines: What major suppliers provide in 2025

Why picking out the Right Liquid Filling equipment company Impacts Your Output top quality

Liquid Filling Machine available for purchase: Which design suits Your Industry Application greatest?

improvements in Liquid Filling Machines: What foremost suppliers present in 2025

top liquid filling machine maker are continuously pushing the boundaries of technological know-how, introducing impressive options that greatly enhance performance and performance. One essential development is The mixing of Superior sensor engineering, enabling serious-time monitoring of fill levels and automated adjustments to keep up accuracy. One more substantial innovation is the development of a lot more adaptable machines which can manage a broader variety of liquid viscosities and container measurements, lowering the need for multiple machines. enhanced cleaning and sterilization methods will also be attaining prominence, specially in industries with stringent hygiene specifications. On top of that, suppliers are incorporating clever technological know-how, letting for remote monitoring, diagnostics, and predictive routine maintenance, reducing downtime and maximizing productivity. the usage of robotics and automation can be increasing, enabling completely automatic filling lines with minimum human intervention. When analyzing various equipment, consider these improvements and pick a product that incorporates the most recent engineering to improve your generation procedures.

Why Choosing the suitable Liquid Filling equipment Manufacturer Impacts Your Output top quality

picking out the ideal liquid filling equipment maker read more includes a profound influence on your output high quality. A reliable company not just provides large-quality equipment but also provides knowledge, assistance, plus a commitment to your good results. A top-tier manufacturer will get the job done closely with you to know your certain requires and advise essentially the most acceptable alternatives. they're going to deliver custom made machine configurations to improve your production procedures and make certain regular, accurate filling. Additionally, a responsible producer will offer you extensive training and technological assist to make sure your machines run effortlessly and effectively. inside the function of a problem, they are going to give prompt and reliable restore expert services to reduce downtime. By partnering having a trusted manufacturer, you achieve use of a prosperity of information and working experience that will help you improve your products excellent, minimize waste, and enhance your Over-all operational efficiency. It’s essential to take into consideration things like certifications and sector popularity when generating your conclusion.

Liquid Filling Machine for Sale: Which Model matches Your Industry software Best?

discovering the ideal liquid filling machine available for sale requires watchful thought of your unique business application. unique industries have various requires, and The best equipment will change according to the variety of liquid being loaded, the container sizing, and the desired creation fee.

Pharmaceuticals: call for machines with substantial precision, sterilization abilities, and compliance with rigid regulatory benchmarks. Aseptic filling machines are often necessary.

Cosmetics: Demand equipment that sustain aesthetic charm and prevent spills. specific volume Management and Mild dealing with are vital.

food items and Beverage: will need devices which are quick to wash and sanitize, usually necessitating stainless-steel design to satisfy hygiene requirements.

chemical compounds: Necessitate equipment manufactured from corrosion-resistant products and Outfitted with security capabilities to safeguard workers.

private treatment: gain from multipurpose equipment that will tackle a range of liquid viscosities and container designs.

prior to making a order, carefully assess your precise requirements and pick a design that's tailored in your industry software. take into account aspects including filling precision, pace, flexibility, and simplicity of upkeep.

The future of automated filling is bright, with improvements continually increasing effectiveness and precision. By cautiously assessing your preferences, deciding on the ideal liquid filling equipment for sale, and partnering with a reliable liquid filling equipment producer, you can enhance your production procedures, enhance your output top quality, and obtain sustained results during the competitive Market. Embrace automation and put money into the future of your company currently.

Mike Vitar Then & Now!

Mike Vitar Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now! Suri Cruise Then & Now!

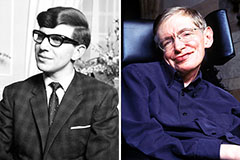

Suri Cruise Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!